Our Company

Our Company

Urschel Food Cutting Equipment is Built to Last

Nobody in the world builds a machine as well as Urschel Laboratories, Inc. With the company's longstanding history and design philosophy, it is easy to see how quality is built into every part manufactured. This philosophy began in 1910 and continues on with Urschel employees who are dedicated to this high level of excellence and precision.

Nobody in the world builds a machine as well as Urschel Laboratories, Inc. With the company's longstanding history and design philosophy, it is easy to see how quality is built into every part manufactured. This philosophy began in 1910 and continues on with Urschel employees who are dedicated to this high level of excellence and precision.

A Company Built on History

Why does a company that designs and manufactures food cutting machines call themselves a "laboratory"? It all started when William Urschel designed the Gooseberry Snipper in 1910 to remove the stem and blossom ends from gooseberries. The Gooseberry Snipper was a grand mechanical triumph that signaled the start of a small company in Valparaiso, Indiana that would later become Urschel Laboratories, Inc., known worldwide for precision-engineered size reduction equipment. He continued to experiment with new ideas and invented many revolutionary machines for the food industry. Because of this extensive research and development, the company took on the name "laboratory". The company, to this day, is still owned and operated by direct descendants of William Urschel, and we retain the name Urschel Laboratories because of a commitment to continuous development of new food processing machines, the improvement of existing Urschel® machines, and the development of innovative solutions to size reduction applications.

Why does a company that designs and manufactures food cutting machines call themselves a "laboratory"? It all started when William Urschel designed the Gooseberry Snipper in 1910 to remove the stem and blossom ends from gooseberries. The Gooseberry Snipper was a grand mechanical triumph that signaled the start of a small company in Valparaiso, Indiana that would later become Urschel Laboratories, Inc., known worldwide for precision-engineered size reduction equipment. He continued to experiment with new ideas and invented many revolutionary machines for the food industry. Because of this extensive research and development, the company took on the name "laboratory". The company, to this day, is still owned and operated by direct descendants of William Urschel, and we retain the name Urschel Laboratories because of a commitment to continuous development of new food processing machines, the improvement of existing Urschel® machines, and the development of innovative solutions to size reduction applications.

Urschel Design Philosophy: Simplicity, Efficiency, and Precision

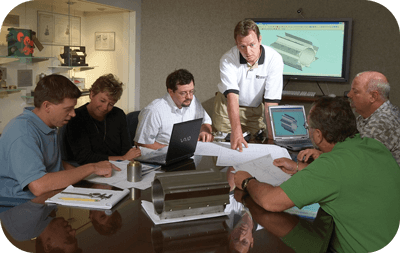

Urschel Engineers work together to create innovative, efficient solutions to your processing requirements. Every challenge is unique, every customer different. That is why every machine Urschel manufactures is an original Urschel design that is simple to use, reduces waste, and improves end product in some outstanding way.

Urschel Engineers work together to create innovative, efficient solutions to your processing requirements. Every challenge is unique, every customer different. That is why every machine Urschel manufactures is an original Urschel design that is simple to use, reduces waste, and improves end product in some outstanding way.

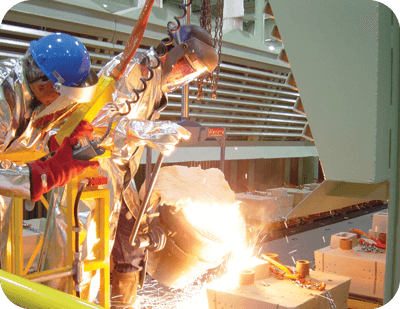

At Urschel Laboratories every machine is constructed individually with meticulous care and pride without the use of assembly lines. Highly-skilled personnel give careful attention to every detail of machine assembly.

In-depth research and development is ongoing to produce the most accurate, high performance and long-lasting parts.

On-site foundries offer the latest state-of-the-art technology and ensure maximum quality control.