Affinity® Dicers

3 Models: U.S.D.A., Dairy Division, Precutter, or Conveyor-Fed

- Maximum power to deliver maximum capacity.

- Robust, heavy-duty sanitary dicer. Dicer design incorporates food contact surfaces highly polished to an Ra 32 finish.

- Food zone completely separate from the mechanical zone to ensure sanitation.

- Hinged swingaway panels ease maintenance. Rounded tube frame and angled/rounded surfaces ease washdowns and deter bacterial growth.

- Dicer designed for continuous operation for uninterrupted production.

- Has the ability to process high-fat, cold-temperature and otherwise normally difficult products. 2- or 3-dimensional cutting is accomplished by adjusting the slice thickness, crosscut, and circular knife spindles for a full range of dices, crumbles/granulations, or strips.

- U.S.D.A, Dairy Division accepted Affinity Dicer accepts in-feed of products up to 7" (178 mm). Ideal for dairy processing plants routinely inspected by the United States Department of Agriculture.

- Affinity Dicer with built-in conveyor feed chute accepts in-feed of products up to 7" (178 mm), or up to 10" (254 mm) in largest single dimension depending on product and assists in feeding and orientation of product.

- Affinity Dicer with precutter offers an all-in-one solution for processing preformed meat logs. More information.

Applications

AFFINITY® DICER WITH CONVEYOR FEED CHUTE

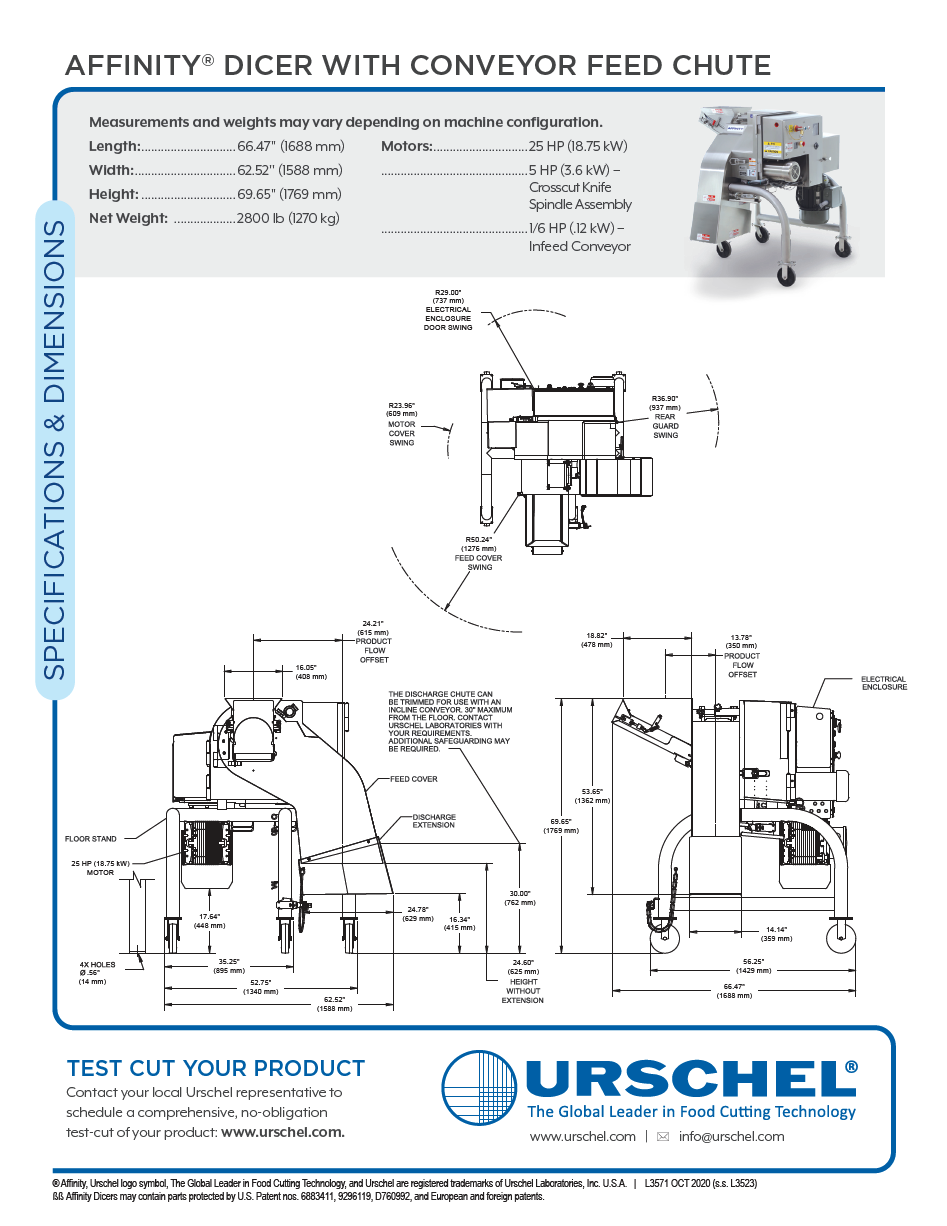

The Affinity® Dicer with built-in conveyor (MAFF) has the ability to process high-fat, cold-temperature, and otherwise normally difficult products. The built-in conveyor assists in feeding and orientation of product. The feed roll and feed drum offer additional assistance transitioning product throughout the cutting zone. Optional outboard bearing supports cutting spindles to assist with heavy-duty applications. Other heavy-duty parts are also available. Sanitary stainless steel design. Food zone is completely separate from mechanical zone. Rounded tube frame limits microbial surface area and promotes self-draining. The dicer provides 2- or 3-dimensional cutting by adjusting the slice thickness, crosscut, and circular knife spindles for a full range of dices, crumbles/granulations, or strips. The Affinity accepts a wide range of infeed products in different shapes and sizes. Large infeed hopper accepts products up to 7" (178 mm), or up to 10" (254 mm) maximum in largest single dimension depending on the product. Large product infeed combined with a powerful 25 HP (18 kW) motor achieves maximum capacity.

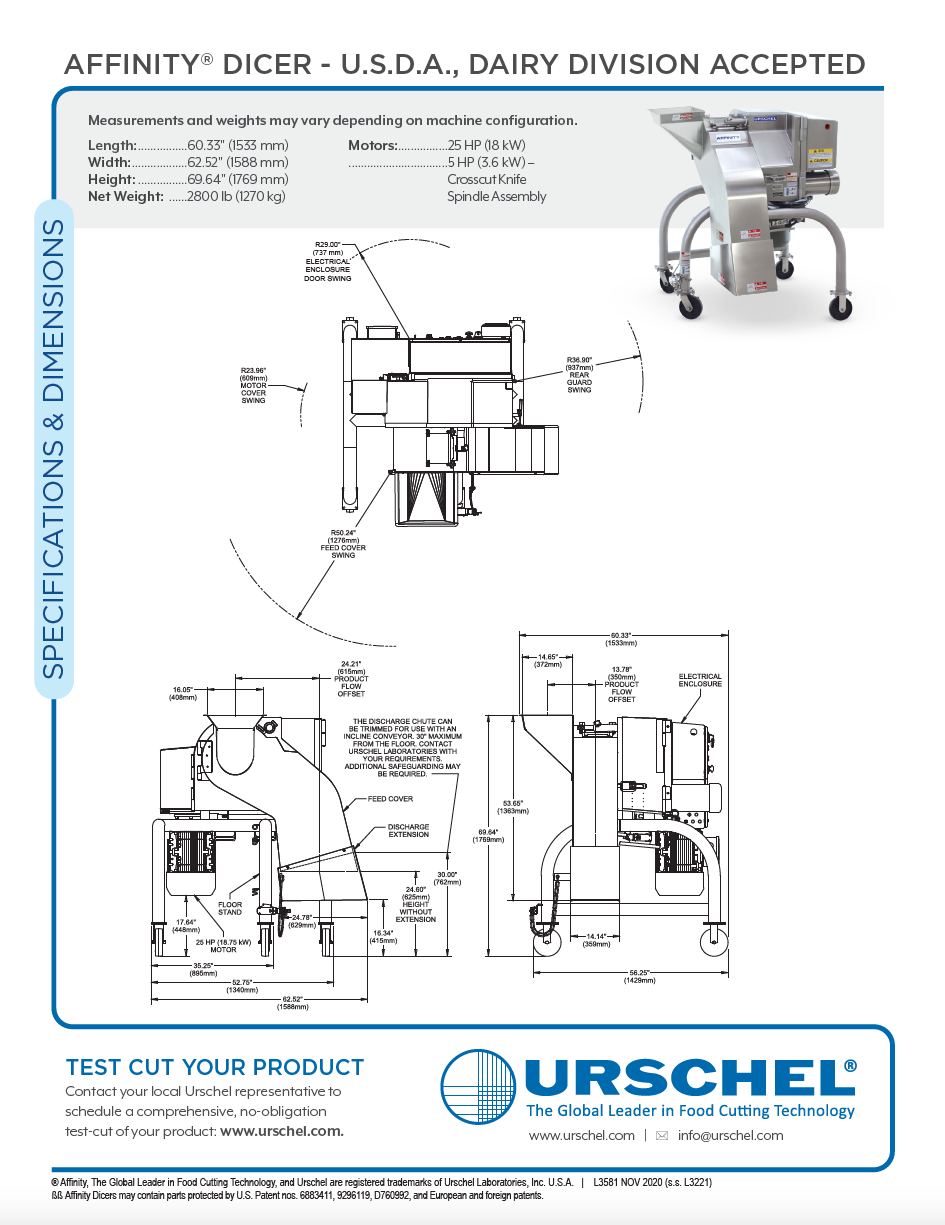

AFFINITY® DICER - U.S.D.A., DAIRY DIVISION ACCEPTED

The Affinity® Dicer (MAFF) U.S.D.A., Dairy Division accepted version has the ability to process high-fat, cold-temperature and otherwise normally difficult products. The feed roll and feed drum offer additional assistance transitioning product throughout the cutting zone. Sanitary stainless steel design. Food zone is completely separate from mechanical zone. Rounded tube frame limits microbial surface area and promotes self-draining. The dicer provides 2- or 3-dimensional cutting by adjusting the slice thickness, crosscut, and circular knife spindles for a full range of dices, crumbles/granulations, or strips. The Affinity accepts a wide range of infeed products in different shapes and sizes. Large infeed hopper accepts products up to 7" (178 mm). It is ideal for dairy processing plants routinely inspected by the United States Department of Agriculture.

AFFINITY® DICER - WITH BUILT-IN PRECUTTER

The Affinity® Dicer (MAFF) with built-in precutter offers an all-in-one solution for processing of preformed meat logs. The feed roll and feed drum offer additional assistance transitioning product throughout the cutting zone. Optional outboard bearing supports cutting spindles to assist with heavy-duty applications. Other heavy-duty parts are also available. Sanitary stainless steel design. Food zone is completely separate from mechanical zone. Rounded tube frame limits microbial surface area and promotes self-draining. The dicer provides 2- or 3-dimensional cutting by adjusting the slice thickness, crosscut, and circular knife spindles for a full range of dices

Machine Specs

AFFINITY Dicer, U.S.D.A., Dairy Division Accepted

AFFINITY Dicer with Built-in Conveyor Feed Chute

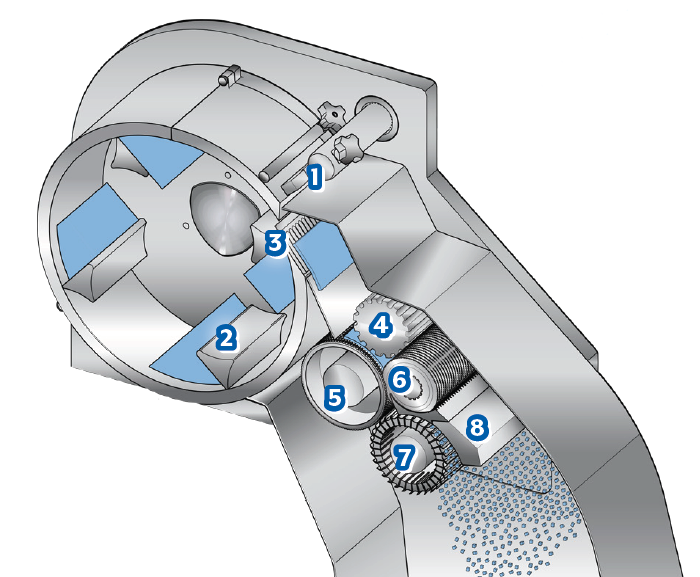

Operating Principle

Affinity® Dicers

- Adjustable Slice Gate

- Impeller Paddles

- Slicing Knife

- Feed Roll

- Feed Drum

- Circular Knives

- Crosscut Knives

- Stripper Plate

Types of Cuts

Slices

Slice thickness: 1/8 to 3/4” (3.2 to 19.1 mm)

Dices, Crumbles, Strips

2 and 3-dimensional cutting involves adjusting the slice thickness and using the required circular or crosscut spindles.

Circular Knife Spindle

1/8 to 3” (3.2 to 76.2 mm)

Crosscut Knife Spindle

1/8 to 2” (3.2 to 50.8 mm)

Shreds

Fine, medium, and coarse shreds can be produced on hot or chilled cooked meat products by using shredding disc spindle in place of the crosscut knife spindle.