Comitrol® Processor Model 9310

High Capacity, Controlled Particle Size Reduction

- Replaces the Comitrol Processor Model 9300.

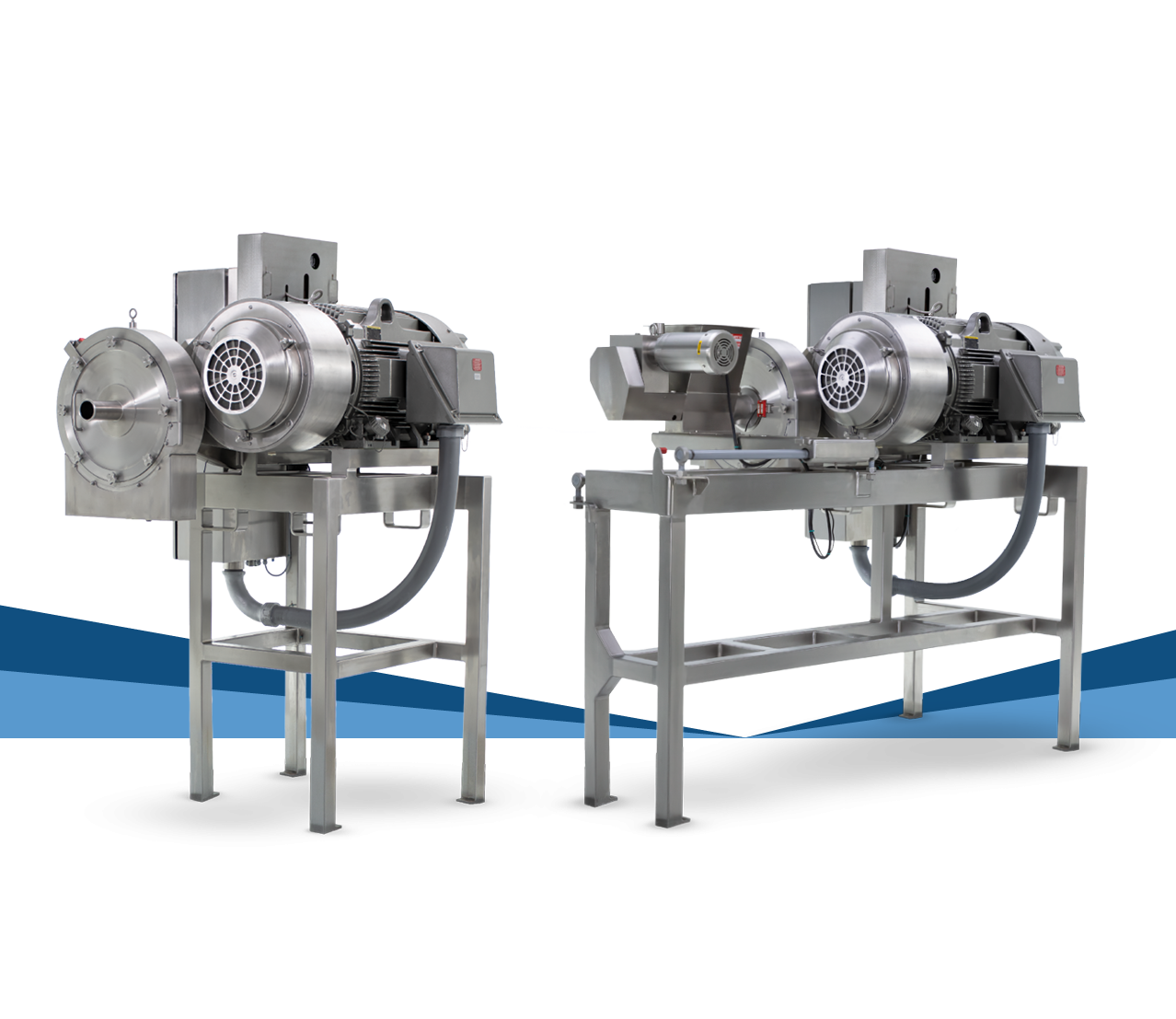

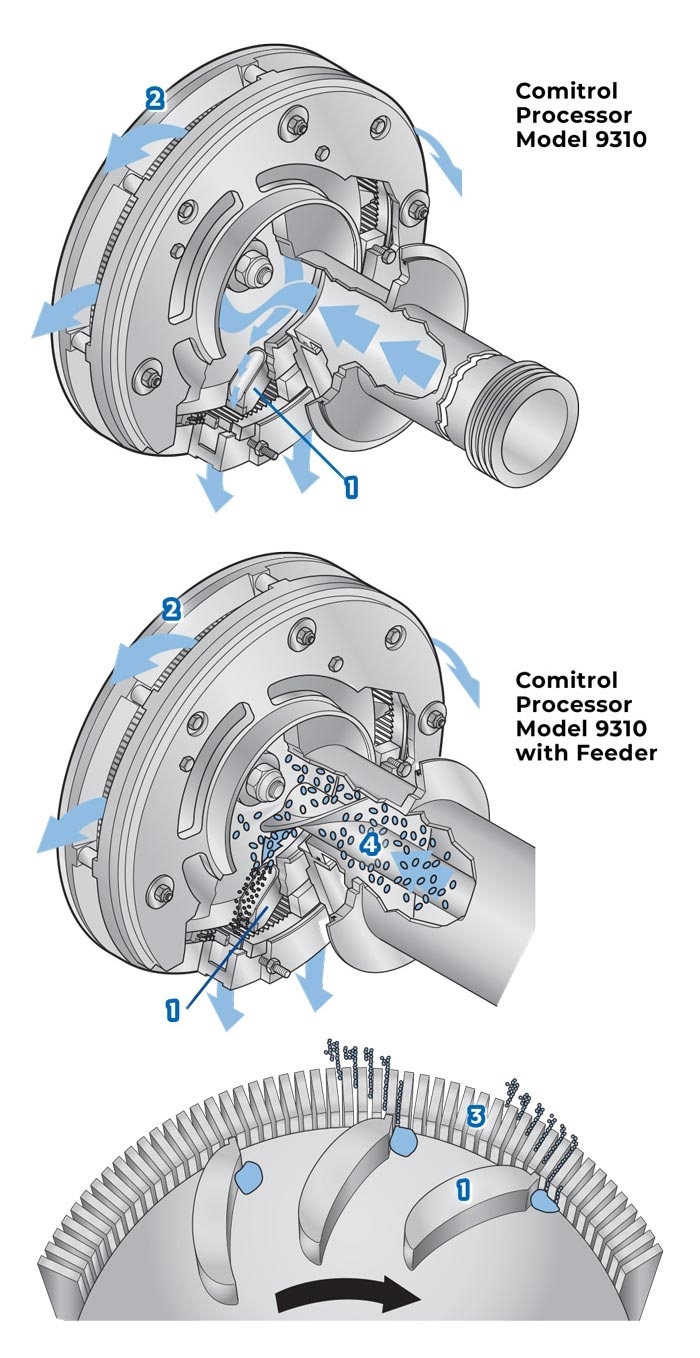

- The Comitrol Processor Model 9310 is available in two different models (1) Pump-fed or (2) Equipped with a hopper-fed screwfeeder

- Features an integrated HMI. Integrated standard HMI monitors amperage, and temperature of the motor bearings and inside air of the support housing, identifies misaligned safety sensors, and flags machine runtime, motor loads, and overfeeding issues.

- The improved airflow system incorporates a new screened-in fan within a support housing working to consistently cool the motor and belt and deter the support housing from thermally expanding. Air ducts divert warm air away from the product zone. Stainless steel mesh on fan screen may be easily removed for routine cleaning.

- Robust cutting enclosure is contoured to alleviate product pressure inside the impeller with seals firmly seated for containment of processed products. Different bolt-on discharge designs are available to suit different production lines.

- Extended shaft spindle inserts additional space between the spindle and cutting enclosure and maintains a primary and labyrinth seal to deter product from entering the spindle bearings. It is also outfitted with a bypass to prevent build-up and back-up of product.

- Recommended for particle size reduction when the final product will be a slurry, paste, or liquid.

- Equipped with a 12" (305 mm) microcut head and impeller, the 9310 is designed for one-pass size reduction due to the rapid velocity speed of the impeller.

- Features continuous operation for uninterrupted production and simplified design to ease cleaning and maintenance.

Applications

The Comitrol® Processor Model 9310 replaces the 9300. Features include an integrated HMI, improved airflow system, newly designed cutting enclosure, and an extended shaft spindle. The machine is equipped with the 12" (304.8 mm) diameter Microcut Head and is available in a pump-fed or screw-fed model. The Microcut Head combined with a powerful motor produces the ultimate particle size reduction in terms of precision and capacity. The 9310 is recommended for slurry, paste, or liquid applications. Sold to process a variety of items including nut milk, fruit purees, baby food, nut butter, vegetable juices, meat, poultry, meat/poultry by-products, soy reductions, and reduction of active pharmaceutical ingredients. Choose between the 9310 equipped with a screw feeder or the pump-fed version.

Generally, maximum input size in any dimension should not exceed 3/8" (9.5 mm). Both models feature continuous operation for uninterrupted production and are designed for easy cleanup and maintenance.

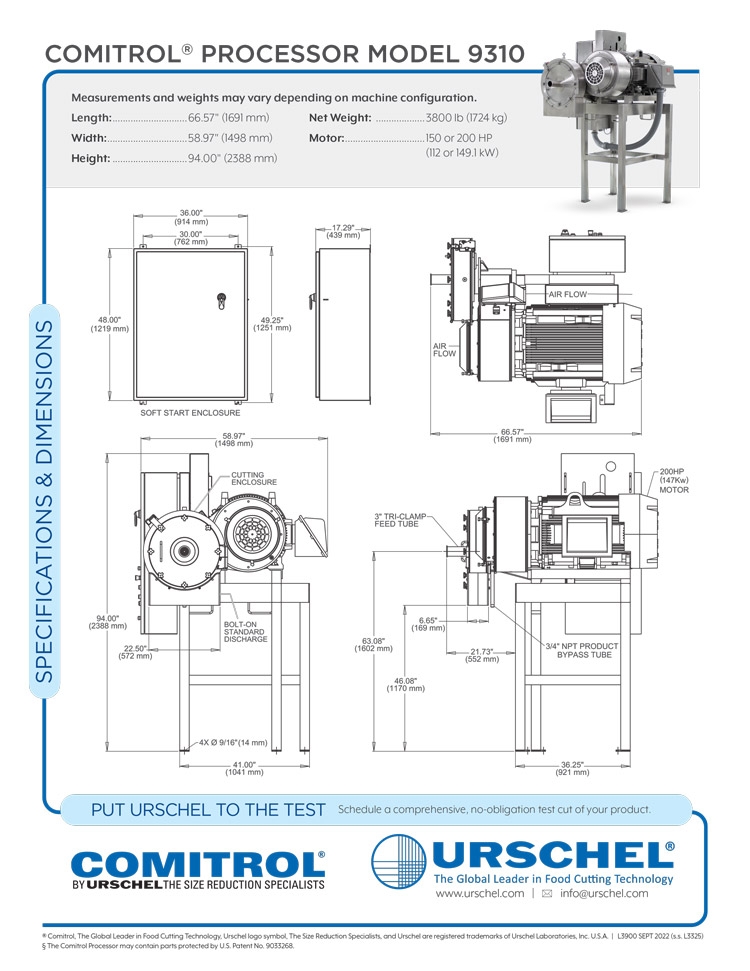

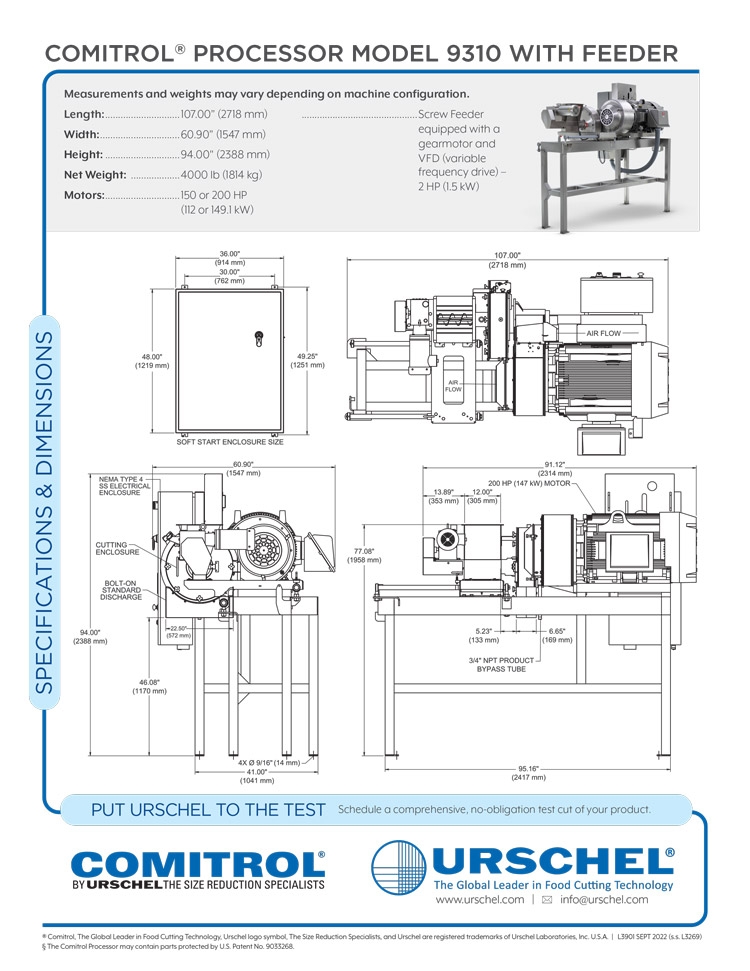

Machine Specs

Comitrol® Processor Model 9310

Operating Principle

Comitrol® Processor Model 9310

- Impeller

- Microcut Head

- Microcut Blades

- Feed Screw

Types of Cuts

Microcut Head

Utilizes 12" (304.8 mm) diameter Microcut Head to produce particle sizes ranging from coarse to fine emulsions. To ensure the proper combination of cutting parts, Urschel recommends a free-of-charge test cut of your application. Contact Urschel for more information.