Comitrol® Processor Model 5600

Maximum Power Plus Positive Feed Assistance

- Common applications include: vegetable processing, curry, ginger, coconut meat, beef/poultry/seafood and byproducts, and textured vegetable protein.

- The 5600 benefits from the unique Comitrol size reduction principle at an increased impeller speed of 5,600 revolutions per minute.

- Maximizes capacity using a powerful 100 HP (75 kW) motor combined with a 5 HP (3.7 kW) screw feeder equipped with a gearmotor and VFD (variable frequency drive).

- Features continuous operation for uninterrupted production, and is designed for easy cleanup and maintenance.

- Product input is dependent on the style of reduction head, impeller selection, and spacing within the head. Generally, maximum input size in any dimension should not exceed 2-1/2" (63.5 mm).

Applications

The Comitrol® Processor Model 5600 maximizes capacity. A powerful 100 HP (75 kW) motor and a 5 HP (3.7 kW) screw feeder equipped with a gearmotor and a VFD (variable frequency drive) completely optimize throughput. The 5600 benefits from the unique Comitrol size reduction principle at an increased impeller speed of 5,600 revolutions per minute. Stainless steel construction ensures maximum durability and sanitation. The machine features continuous operation for uninterrupted production, and is designed for easy cleanup and maintenance.

Common applications include: vegetable processing, curry, ginger, coconut meat, beef/poultry/seafood and byproducts, and textured vegetable protein. Product input is dependent on the style of reduction head, impeller selection, and spacing within the head. Generally, maximum input size in any dimension should not exceed 2-1/2" (63.5 mm).

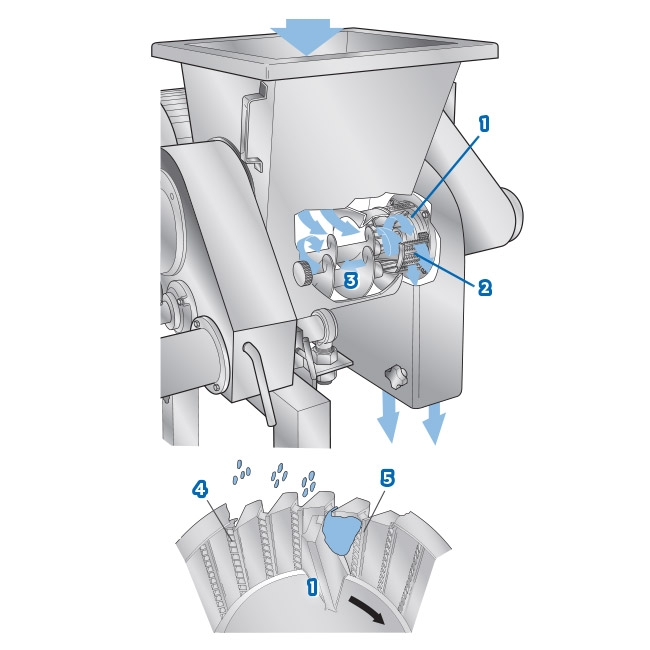

Operating Principle

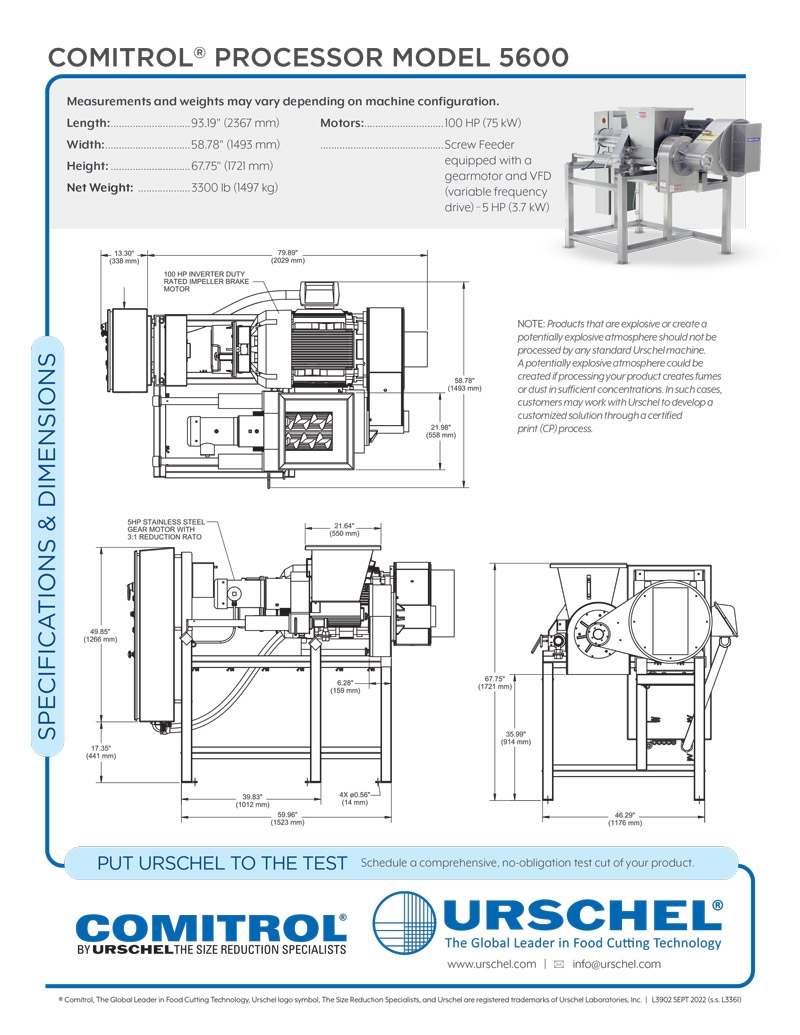

Comitrol® Processor Model 5600

- Impeller

- Cutting Head

- Screw Feeder

- Horizontal Separators

- Vertical Knives

Types of Cuts

Cutting Head

Utilizes 6" (152.4 mm) diameter Cutting Heads paired with a variety of impellers to produce coarse to fine reductions.

NOTE: Products that are explosive or create a potentially explosive atmosphere should not be processed by any standard Urschel machine. A potentially explosive atmosphere could be created if processing your product creates fumes or dust in sufficient concentrations. In such cases, customers may work with Urschel to develop a customized solution through a certified print (CP) process.