Comitrol® Processor Model 1500

Liquid & Finishing Applications

- Recommended for specific applications including finishing liquids or slurries.

- Maximum input size in any dimension should not exceed 3/8" (9.5 mm).

- Available 15, 30, or 40 HP (11.2, 22.4, or 30 kW) Motor.

- Features continuous operation for uninterrupted production and simplified design to ease cleaning and maintenance.

Applications

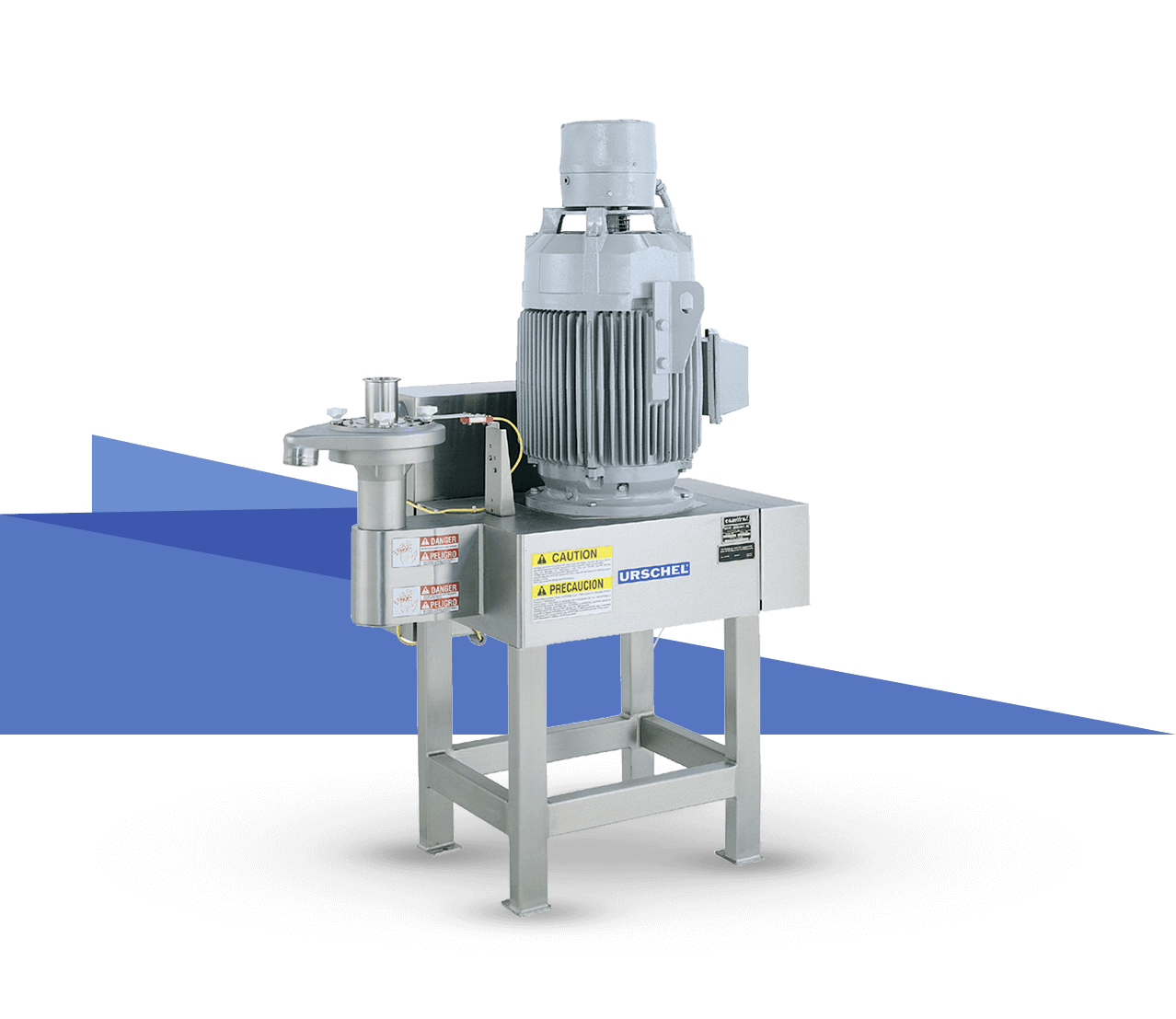

The Comitrol® Processor Model 1500 is specifically designed for viscous and liquid product applications including finishing. It utilizes the Microcut 6" (152.4 mm) diameter style reduction heads. Recommended for specific applications where refining or finishing of free-flowing liquids or viscous slurries is desired. Product input is dependent on the style of reduction head, impeller selection, and spacing within the head. Generally, maximum input size in any dimension should not exceed 3/8" (9.5 mm).

The Model 1500 is equipped with the microcut cutting head and corresponding impeller to process a variety of products including fruit nectars, soy beans, ketchup, barbecue sauce, vegetable purees, beverage concentrates, and creams and ointments. The machine features continuous operation for uninterrupted production, and is designed for easy cleanup and maintenance.

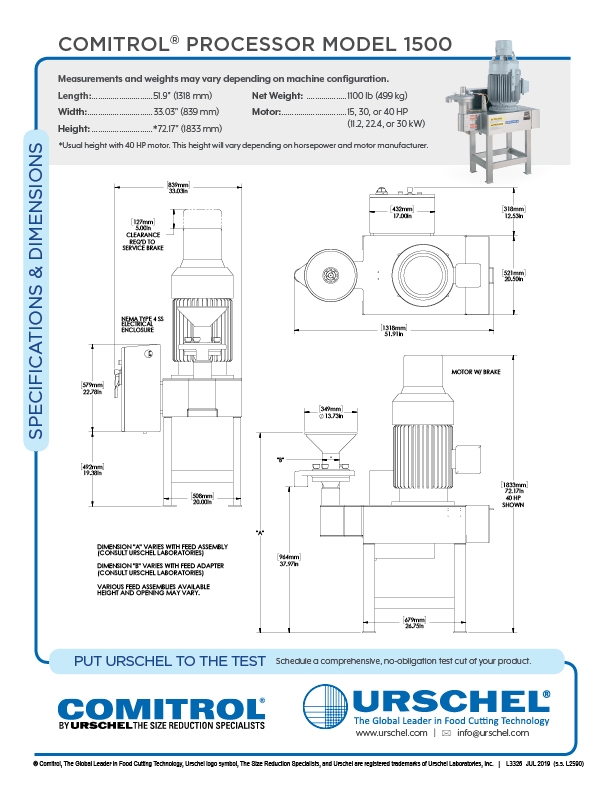

Machine Specs

* USUAL HEIGHT WITH 40 H.P. MOTOR IS SHOWN. THIS HEIGHT WILL VARY DEPENDING ON HORSEPOWER AND MOTOR MANUFACTURER. CONSULT URSCHEL LABORATORIES, INC. TO DETERMINE SPECIFIC HEIGHT.

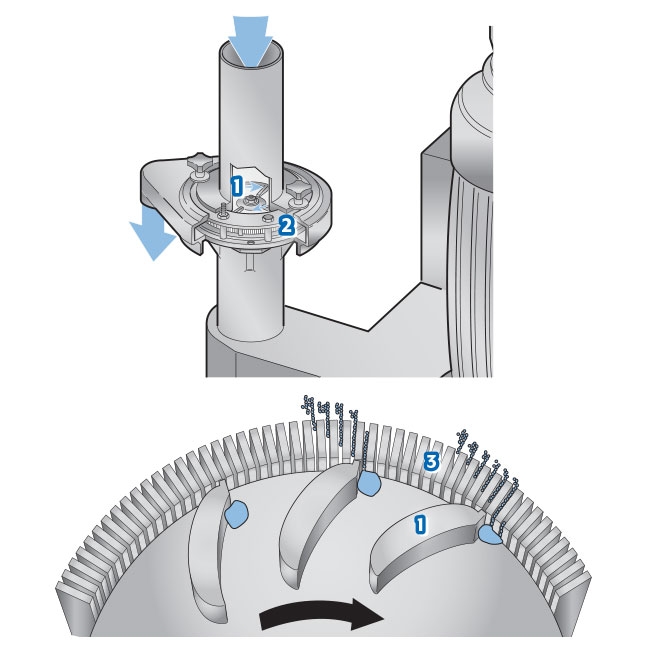

Operating Principle

Comitrol® Processor Model 1500

- Impeller

- Microcut Head

- Microcut Blades

Types of Cuts

Microcut Head

Utilizes 6" (152.4 mm) diameter Microcut Head to produce particle sizes ranging from coarse to fine emulsions. To ensure the proper combination of cutting parts, Urschel recommends a free-of charge test cut of your application. Contact Urschel for more information.

NOTE

Products that are explosive or create a potentially explosive atmosphere should not be processed by any standard Urschel machine. A potentially explosive atmosphere could be created if processing your product creates fumes or dust in sufficient concentrations. In such cases, customers may work with Urschel to develop a customized solution through a certified print (CP) process.