VERSATILE SHREDDER: MODEL M6

VERSATILE SHREDDER: MODEL M6

The Urschel® Model M6 offers a wide variety of hand-pulled look shreds from cooked-chilled or cooked-hot beef, pork, or poultry. Feed discs work together with special shredding discs or blunt knives to produce a wide variety of shred consistencies from coarse to fine. Various shred lengths are also possible depending upon set-up. The Model M6 operates continuously at high production capacities and is designed for easy cleanup and maintenance. Contact Urschel to learn more.

|

|

|

| SHREDDING DISCS | BLUNT CROSSCUT KNIVES |

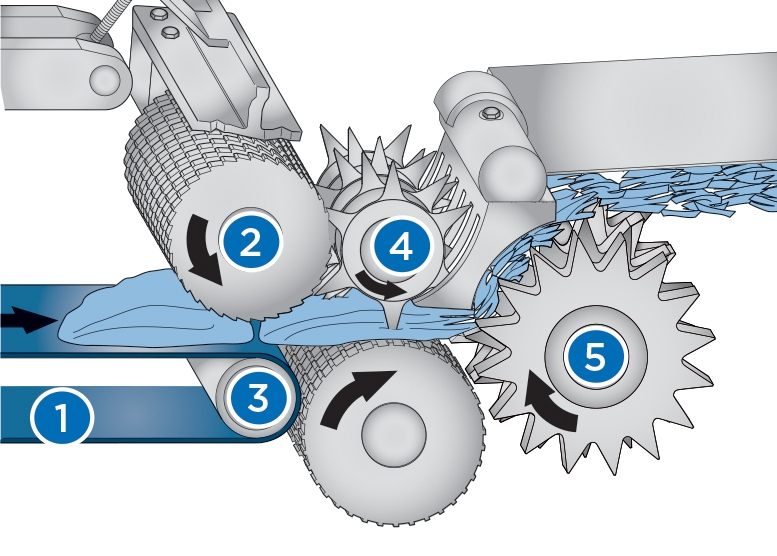

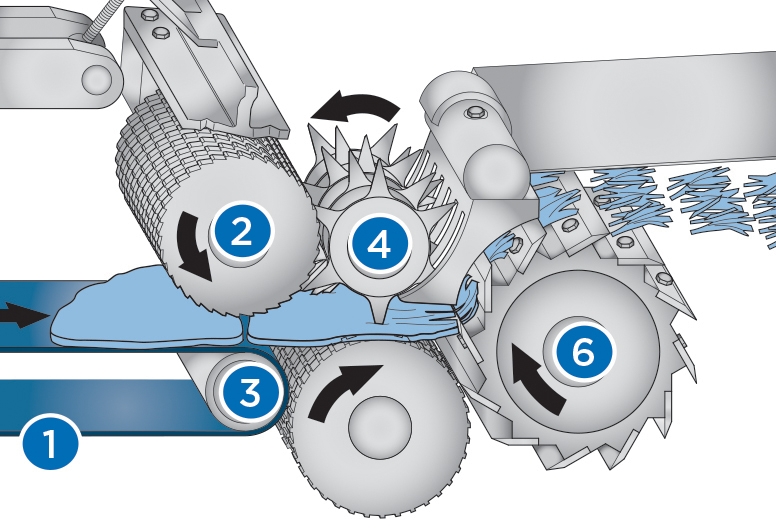

OPERATING PRINCIPLE

Shredding: Product is delivered onto a high speed feed belt [ 1 ]. This belt carries the product to the feed roll [ 2 ]. Product is pinched between the feed roll and the drive roll [ 3 ] at the end of the feed belt. The feed roll, which is spring loaded and adjustable, allows product of varying thicknesses to move through the shredding set-up while intentionally compressing the product. Product is forced into feed discs [ 4 ] and removed from the feed discs by the stripper plate, which acts as a shear edge for the shred spindle. The product then moves directly into the shredding discs [ 5 ] or blunt knives [ 6 ] producing desired shreds.

Due to application differences in product temperature and texture of your specific product, a no-cost product test in our Product Test Cutting Facility is strongly recommended. For more information on shredding set-ups regarding your application, contact your local Urschel representative.